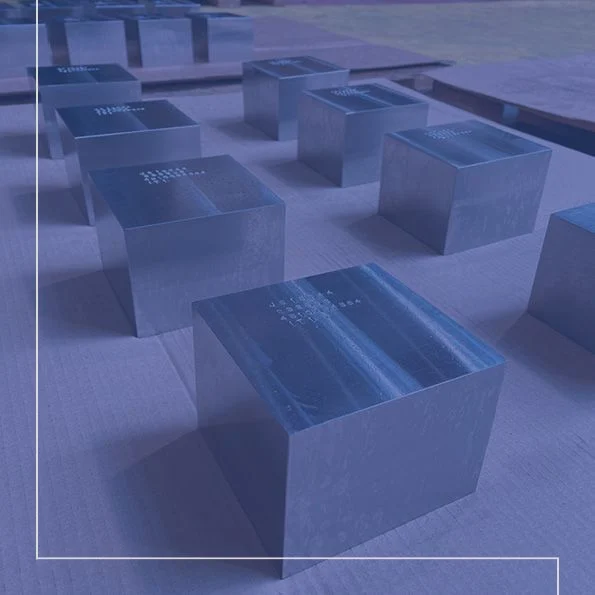

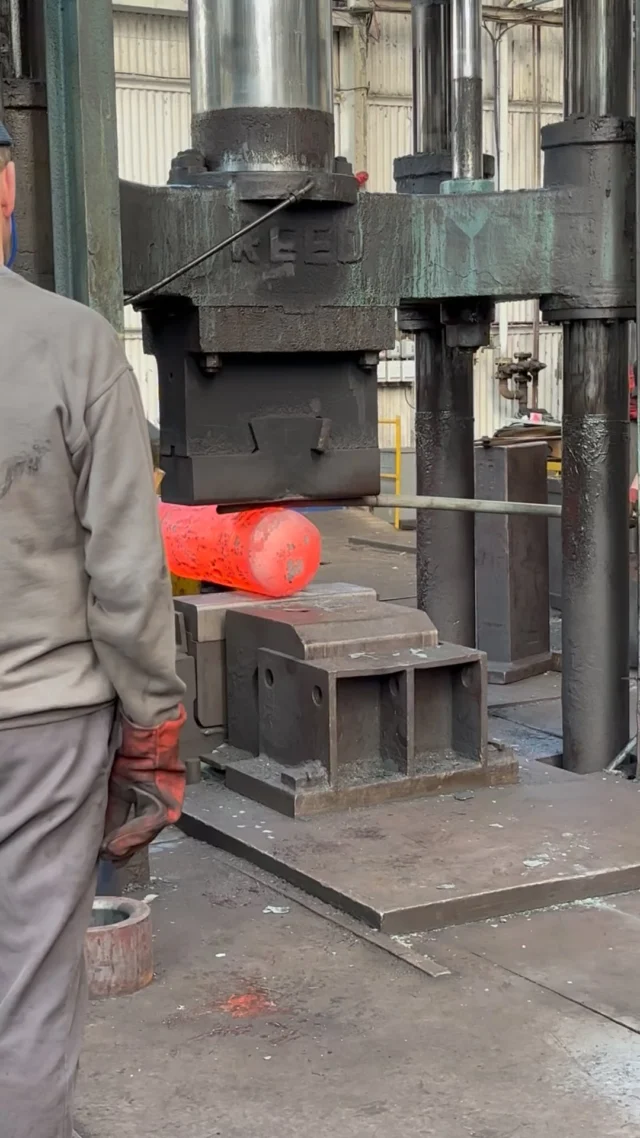

Get to know our own branded die steels, with the Somers magic mix.

No.5 Electem

Ni-Cr-Mo Die Steel

- Recommended as the standard die block steel

- Water / Oil quenched tempered die steel

Typical analysis %

C 0.55

Si 0.30

Mn 0.80

Ni 1.40

Cr 0.90

Mo 0.35

V 0.07

- Normally supplied in the OH&T condition to a hardness range specified by the customer

- Supplied annealed for hardening and tempering after sinking of impression by the customer, or hardened and tempered to suit customer requirements

- Recommended pre-heat temperature 200°C (392°F) min.

Tempering Curve No.5 Electem

This tempering graph indicates the approximate range of hardness expected following heat treatment. The upper and lower limits are indicated but hardness may vary, being dependent on bulk of material, chemical analysis, soaking time and temperature during hardening and subsequent tempering time.

Somdie

A Superior Ni-Cr-Mo-V General Purpose Die Steel

- This die steel is recommended where additional toughness is required in a general purpose die block

- Oil quenched and double tempered

Typical analysis %

C 0.55

Si 0.30

Mn 0.85

Ni 1.60

Cr 1.20

Mo 0.50

V 0.10

- Can be supplied to a maximum hardness of 477 BHN depending on the size of block and impression depth

- Recommended pre-heat temperature 200°C (392°F) min

Both ‘Electem No.5’ (DIN 1.2713) and ‘Somdie’ (DIN 1.2714) are available in round bar and rectangular sections. Materials can be sawn to customer requirements and supplied in the required hardness range. Our Die blocks are also regularly supplied with sawn dovetails to customer drawings.