Valves are used as a device to regulate and control the flow of gas, liquid, slurries and fluidized solids in the oil and gas forging sector. They also prevent backflow or relieve pressure, passageways can be opened, closed or marginally obstructed with the use of a valve.

A wide variety of valves are available in various configurations for on/off control, different fluids, materials, temperatures and pressures. The most common types of valve include Diaphragm, Globe, Gate, Parallel Slide, Ball, Knife Gate, Butterfly, Check, Plug, Piston, Pinch and Sluice.

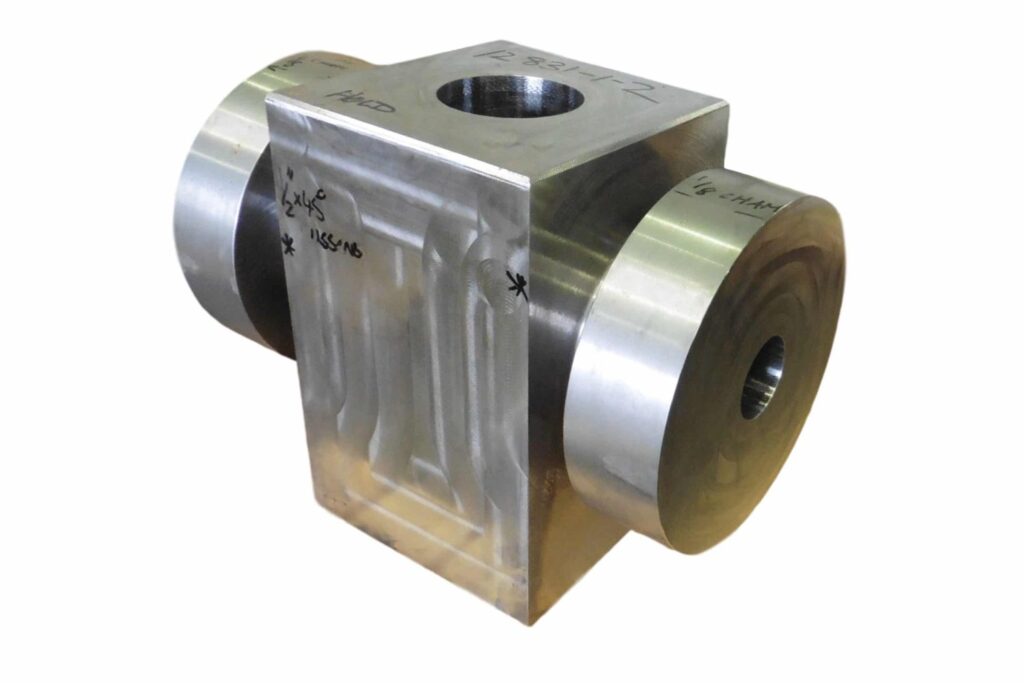

The most common production of good quality valves is either through forging or casting, but what are the benefits and weakness of each – forged valves vs cast valves. Forged valves are produced by shaping the metal in its solid form, with the use of heat, tools and dies, to create the valve shape.

Benefits of Forged Valves

The benefits of forged valves include minimising wasted material (due to the fact they are shaped in one solid piece), the strength and reliability of a forged valve means they handle high temperatures and high pressure well with minimal shrinkage, porosity and cracks occurring. Making them perfect to fitted in applications in nuclear, oil and gas and power generation.

Thermal fatigue reduction is a major benefit of forged valves as they have a thinner wall which means if they are heated or cooled quickly it won’t be detrimental to the functionality of the valve.

There are 3 main types of forging that include rolled ring forging, closed die forging and open die forging. Rolled ring forging uses curved discs to deform the metal, closed die shapes the metal into the contours of a die and open die forging deforms the material with a number of compressive forces.

Benefits of Cast Valves

Cast valves are produced from a liquid form of metal that has been melted down and then poured into a valve mould to cool and set. When the metal is completely solid it is broken from the mould and can be produced in a number of detailed and complex sizes and shapes.

Other benefits of cast valves include the fact that they are cost effective due to the fact of reduced labour and time compared to forged valves. But on larger valve bodies they are often more expensive due to the amount of welding and changes needed to try and achieve the same level of quality.

There are number of different types of casting processes, these include pressure casting, shell mould casting, sand casting, gravity casting, investment casting, low-pressure casting and cavityless casting.

In conclusion, castings are ideal for long runs which do not require a high level of integrity, with the biggest benefits being turnaround time and cost. Open die forging are the best forging option and a better solution than castings due to the process achieving greater microstructure and better fatigue resistance. In the long run these will also be more economic.