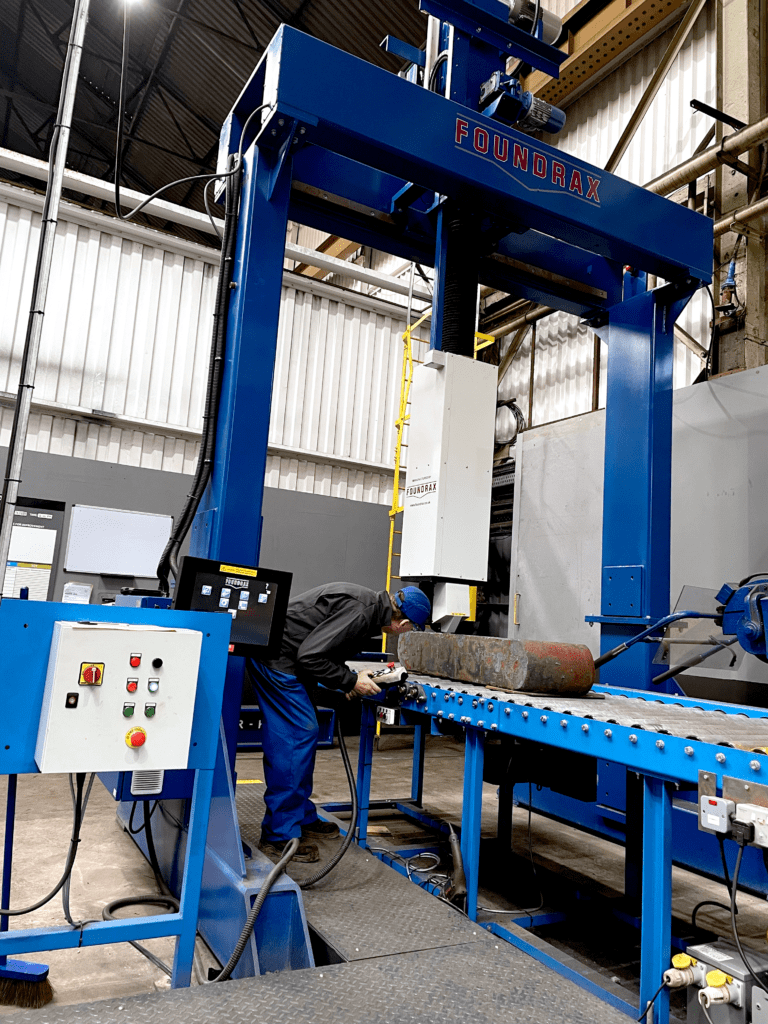

New Brinell Hardness Tester

We are continuing to invest in the latest technologies and equipment to meet the needs of our customers. Our most recent investment is in our testing equipment, investing £180,000 in a Foundrax X-BHD Brinell hardness Tester. Foundrax are widely known to have the highest hardness performance within the industry and build machines to operate in the toughest industrial environments, making it a perfect fit for us. Having this machine will ensure we continue to produce products to the highest quality and remove human error.

Benefits of the Foundrax X-BHD

Investing in this machine was an important decision as it provides a high degree of reliability, repeatability and accuracy that is key to achieving long-term success. Dependable data, and accurate readings that are gathered will allow us to improve performance over time. Other benefits of this machine include auditable processes, pass and fail statuses as well as decreasing the test cycle by 50%.

To ensure parts are produced with the highest level of precision, we will be placing sawing and testing operations in one designated area which will improve and increase workflow. The installation of the integral Brintronic automatic microscope in the machine has opened up a whole new world of possibilities for heavy engineering. With this technology, it is now possible to achieve laboratory-like results in a heavy engineering setting! This new technology allows direct readings and recordings of results to be gathered without any extra effort or time, providing valuable insights and data that can be used to improve processes and efficiency.

Features the machine has include being able to measure multiple diameters and having a heavy-duty static test bed what can test large components. The equipment also has longevity in mind and comes with an internal component of the Type B and Type D test head, which are rated 4x factor of safety, and actuator column is rated at 6x.

Recent Investments

Investment is an integral part of any company’s growth and is at the fore front of our minds. Most recently, we have invested in a new CNC vertical borer and acquired the Oldbury based engineering firm, A&B Richardson Engineering. This has further increased our capabilities and capacity to meet the ever-increasing demand for precision machined forgings. This new investment will ensure that we can continue to provide the highest quality products and services to our customers.