Propeller Shafts Explained

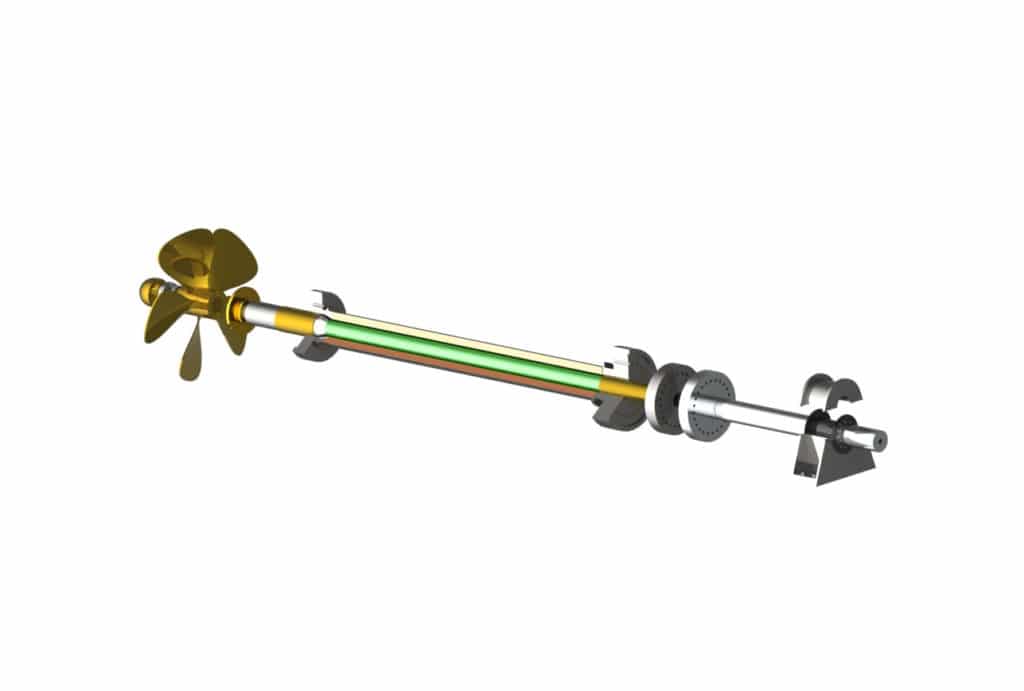

The mechanism required to generate thrust for a boat or ship to move through water is called a propulsion shaft. It is made up of the following main parts: main engine, gearbox, marine shaft and propeller.

In recent years, there has been an increase in the use of heightened propulsion shaft power in the reduction of noise, which has led to a higher importance being placed on more efficient shaft design. The main component used for a propulsion shaft is a propeller shaft. The thrust action on the shaft is a result of the pushing motion generated by a propeller.

Most ships have a main thrust block located at the forward end of the main shaft. The shaft line incorporates all the components including tail shaft, intermediate shaft, thrust shaft, flange coupling, gearbox, engine components and also includes bearings that hold the alignment of the shaft and these include spring, stern tube and strut bearings.

The main reduction gear connects the prime mover to the shaft and its primary function is to reduce the high rotational speed of the engine, so that propellers operate at a lower speed. Here at Somers Forge, we’re global leaders in the supply of propulsion shafts for the marine industry. We use the latest forging techniques and mechanistic innovations to produce shafts and other parts for propulsion shafts of the highest quality.

Supply of Propeller Shaft Lines

We can manufacture propeller shafts in a number of sizes up to lengths of 23 metres, dependent on the application they are required for. We can supply marine propulsion components for super yachts, cruise ships, submarines, naval ships and patrol vessels. Most commonly we produce shafts using C45, 34CrNiMo6, stainless steel and inconel but can offer any material a customer requires. Offering both shaft forging and finished machining if required.

The shaft can be subjected to a number of loading types during use, including torque moment, bending moment, axle thrust force and transverse load. The risk of failure to the system can be increased by weather and sea conditions due to the fact they have a direct effect on the wear, tear and life time of a propulsion shaft.

Enhancing Marine Shaft Durability and Performance

To enhance the durability and performance of our marine shafts, Somers Forge has developed advanced techniques and coatings. Our proprietary Glass Reinforced Coating, Somplas, offers superior protection against corrosion and impact.

This coating has been rigorously tested and approved by DNV, ABS, and Lloyds, ensuring it meets the highest industry standards. In addition to corrosion protection, Somplas is REACH compliant, providing an environmentally friendly option for marine shaft coatings.

Weld Cladding foe Extended Propeller Shaft Life

Recognising the need for extended shaft life in demanding marine environments, Somers Forge has invested in weld cladding technology. This process enhances protection against seawater corrosion, significantly extending the life of both stainless steel and nickel-based alloy shafts.

With ABS approval, Somers Forge is the first UK forge to offer this service, bolstering the nation’s shipbuilding capabilities.

Refurbishment of Propeller Shafts

Do you require a refurbishment of a marine shaft? Here at Somers Forge, we offer a class approved procedure for the refurbishment of all types of shafts which we have developed in-house. Returning shafts to a as ‘new’ condition, with refurbished shafts then able to last for a further 12 years depending on the water environment. Saving you time, money and reducing the lifecycle analysis impact.

Our Marine Forgings

Somers Forge has been a top provider of forged goods for the marine sector since our humble beginnings. We received what was known as Admiralty Approval for the provision of propulsion shafting and other related marine forgings back in 1912.

In addition to manufacturing and refurbishment, Somers Forge offers comprehensive support and services for marine shafts. Our experts are available to provide guidance and assistance throughout the entire process, from material selection to final installation. We pride ourselves on delivering exceptional customer service and ensuring that our clients receive the highest quality products tailored to their specific needs.

Contact Somers Forge Today

If you are in need of forged propeller shafts or a refurbishment of a propulsion shaft, contact Somers Forge today on 0121 585 5959 or fill out our contact form below and one of our experts will get back to you as soon as possible.