Our forged flanges are designed to withstand high pressure and stress, providing a reliable connection between various pieces of equipment. Whether it’s a pipeline in a refinery, a valve in a power plant, or machinery in a steel mill, flanges ensure a tight seal and strong attachment, reducing the risk of leaks or failures. This makes them the preferred choice for applications where performance and durability are paramount.

Types of Forged Flanges

At Somers Forge, we manufacture a comprehensive range of forged steel flanges to suit different industrial applications. These include:

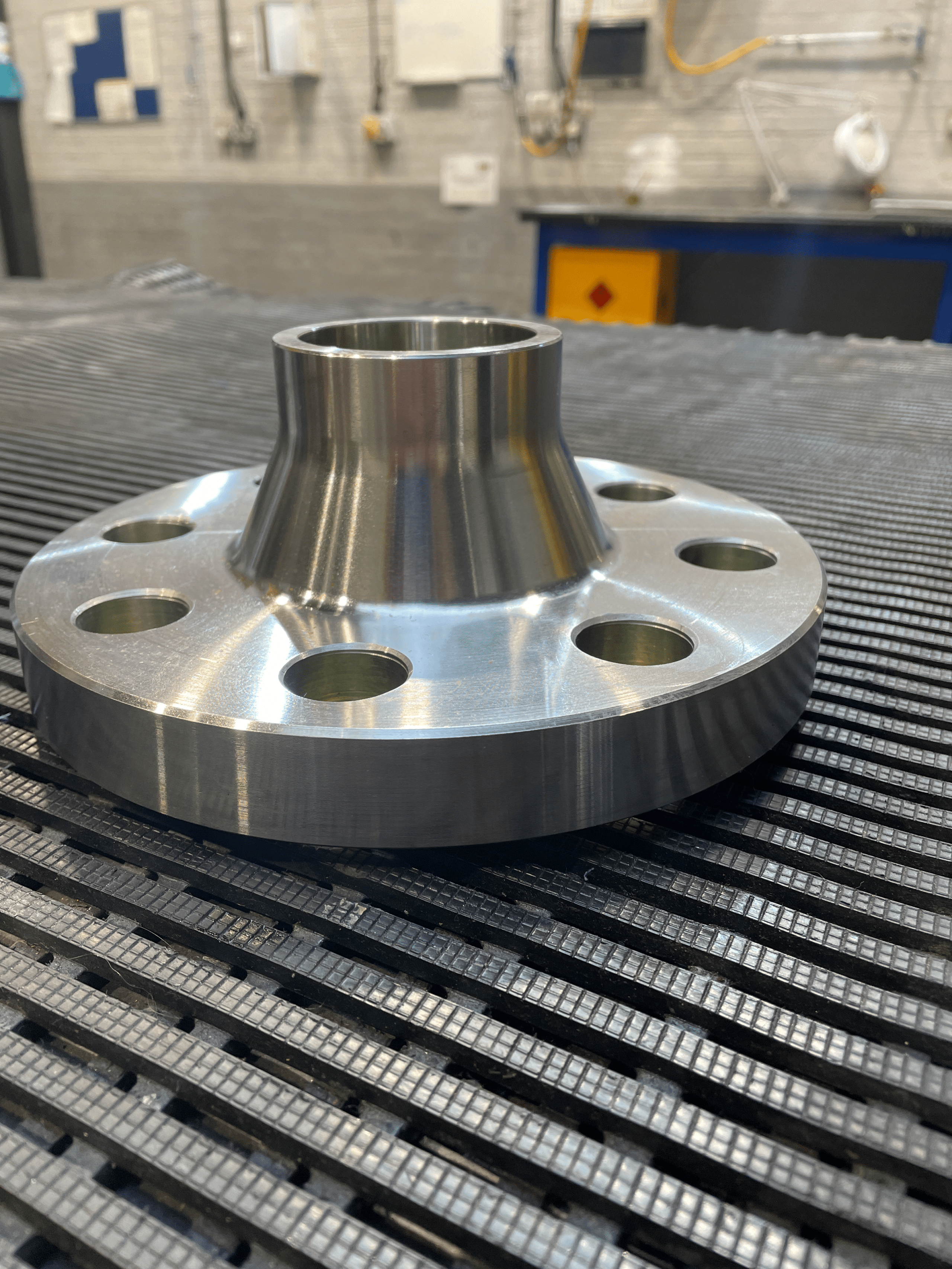

Welding Neck Flanges: Ideal for high-pressure applications, these components have a long, tapered hub that transitions into the pipe or component, ensuring smooth flow and strength.

Slip-On Flanges: Simple to install, these slide over the pipe and are welded both inside and outside for increased strength.

Blind Flanges: Used to close the end of a pipe, these components are crucial in systems that may need to be opened for repairs or inspections.

Socket Weld Flanges: With a socket to insert the pipe, they are ideal for small-diameter, high-pressure systems.

Lap Joint Flanges: Paired with a stub end, lap joints are perfect for systems requiring frequent assembly and disassembly.

Threaded Flanges: For systems that don’t require welding, threaded variants offer a secure connection without compromising on strength.

Whatever the type of forged product you require, Somers Forge can provide bespoke designs crafted to the highest quality standards.

Forged Products For Superior Performance

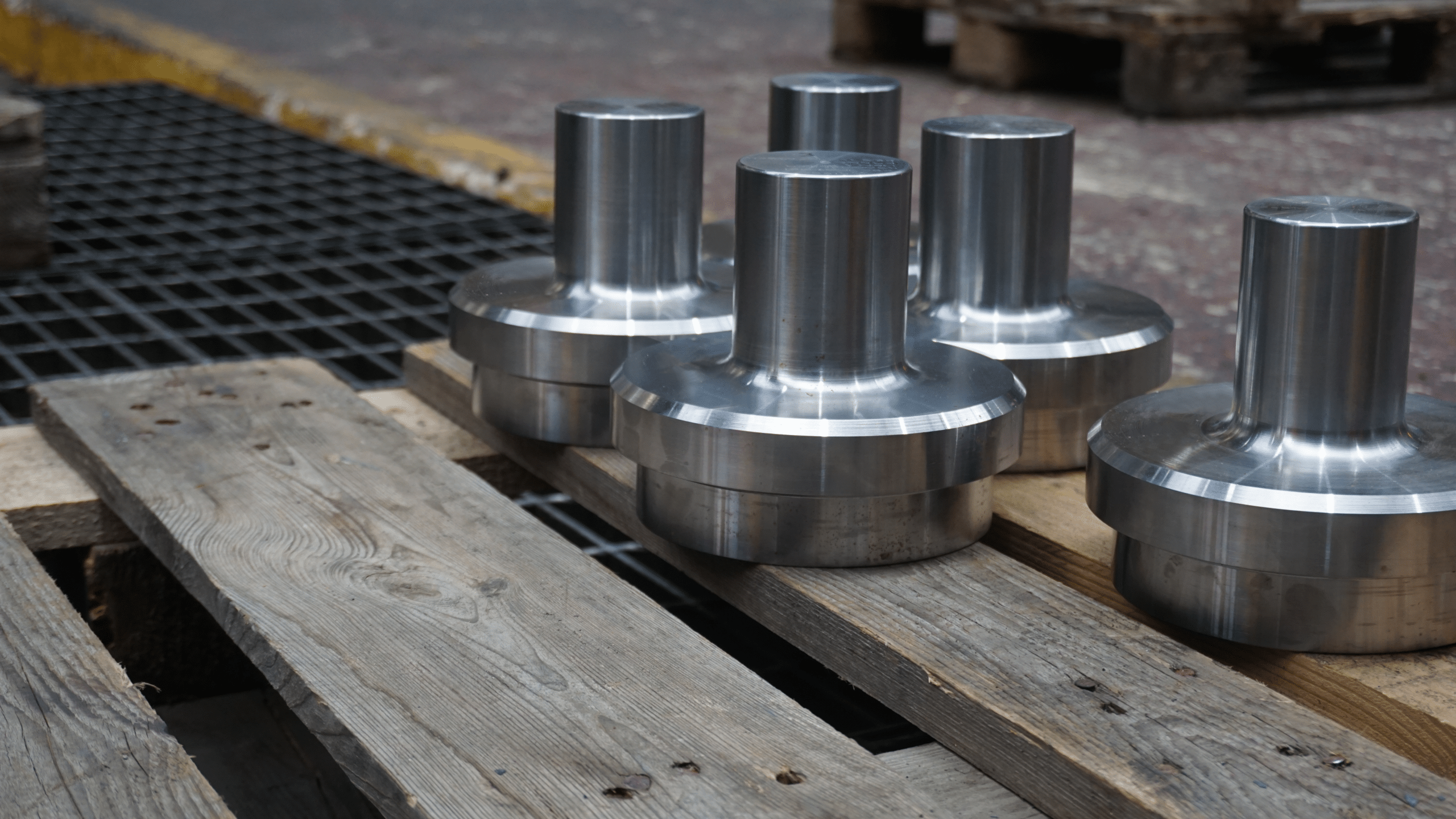

One of the key advantages of flanges over other types of connections is the forging process itself. Forging involves heating the metal to extremely high temperatures and then shaping it under pressure, which refines the grain structure and enhances the material’s strength. The result is a component that offers superior durability, resistance to fatigue, and longer lifespan compared to cast or machined flanges.

Our forged products are particularly suited to environments where corrosion resistance and strength are critical. Somers Forge provides components in a wide variety of materials, including carbon steel, stainless steel, nickel alloys, and exotic materials such as aluminium bronze. We are proud to be a leading supplier of stainless steel flanges, which are frequently used in industries such as chemical processing, marine, and oil & gas due to their exceptional resistance to corrosion.

Custom Forged Flanges For Every Industry

As a trusted name in forging for over 150 years, Somers Forge has the capability to deliver forged products to meet the exact needs of our clients. Whether you need large-diameter components for power generation or compact, high-integrity components for defence applications, we have the expertise and equipment to both meet and exceed your expectations. Our extensive range of forging machinery allows us to manufacture components from as little as 1kg and in excess of 60 tonnes, ensuring no project is too big or small.

We understand that every industry has its own unique set of requirements, which is why we offer bespoke designs for all our forged products. From material selection to heat treatment and machining, every step of the process is tailored to ensure our products perform exactly as they should in their intended environment.

Why Choose Somers Forge?

At Somers Forge, we combine centuries of craftsmanship with cutting-edge technology to produce forged products of unparalleled quality. Here’s why we stand out as a leading global supplier:

- Expertise Across Materials: We forge components from a wide range of materials, including stainless steel nickel alloys, titanium, and more. No matter the application, we have the materials to match your specifications.

- Precision Engineering: Our state-of-the-art forging and machining facilities allow us to manufacture components with incredible precision, ensuring that every part meets the standards of demanding industries.

- Full Certification: All of our forged products come with full certifications, adhering to international standards to give you complete confidence in the quality and integrity of the products you receive.

- Bespoke Solutions: No two projects are the same, and we pride ourselves on delivering tailored solutions that meet the specific requirements of your industry and application.

- Unmatched Durability: Thanks to our forging process, our products offer superior strength, enhanced grain structure, and excellent fatigue resistance, making them ideal for the most challenging environments.

Contact Somers Forge Today

When it comes to high quality forged products, trust the experts at Somers Forge for your needs. With over 150 years of experience and a commitment to precision, we excel at supplying forged components to some of the world’s most demanding industries. Get in touch with us today to discuss your requirements and see how Somers can elevate your projects to new heights.

Read More

Our Forged Products | Oil & Gas | Heat Treatment | Machining | Marine forging