What is machining?

Machining is a manufacturing process whereby material is removed from a workpiece. After the metal component has been forged, it will need to be cleaned up to the customer’s specific requirements and measurements. Many different tools and techniques are used to get the desired size and shape from machining.

We use different machining methods with different tools, these include cutting, boring, turning, drilling, milling, and grinding. With our extensive in-house machine shop we can offer all these machining processes.

Key Machining Processes

Numerous machining procedures are used to achieve these changes, each with its own special instruments and methods:

- Turning: A cutting tool that travels along its axis shapes a revolving workpiece.

- Milling: Material is removed from a fixed workpiece using a revolving cutting tool with many cutting blades.

- Drilling: The workpiece is drilled with holes made by a spinning cutting tool.

- Boring: A cutting instrument makes new holes or enlarges ones that already exist.

- Grinding: To get exact measurements and surface finishes, material is removed using an abrasive wheel.

What are the different machined forging conditions?

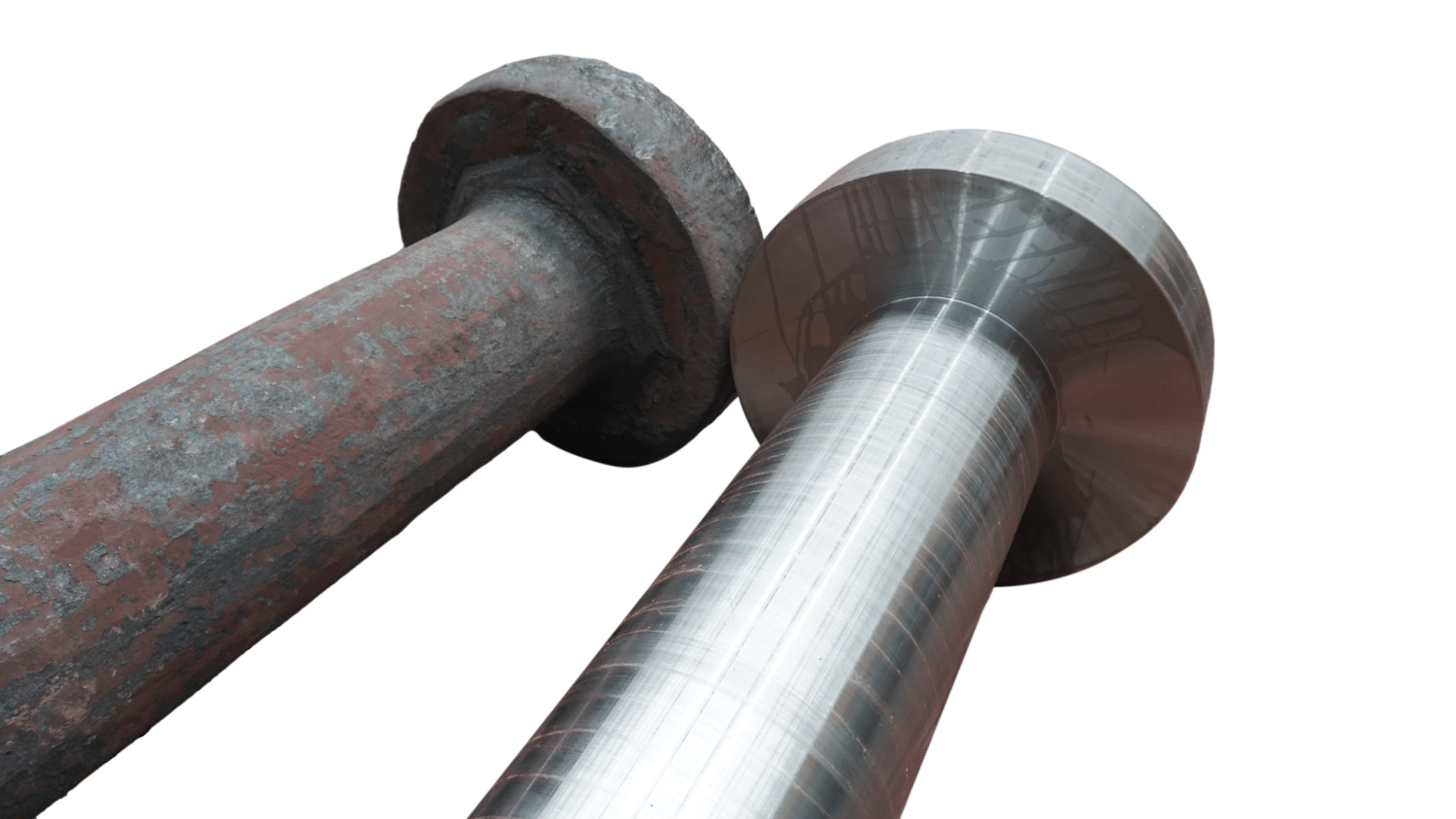

Rough machined component is also known as proof machined forging. This is the process of knocking off the black scale of the forging in preparation for further machining processes. This is a very popular solution and allows customers to finish machining the part themselves and take control of the final dimensions of the part.

Semi machined forging is where more shape is put into components, but the final intricacies will need to be untaken at a later stage.

Finished machined forging is finished to the customers complex or simple surface requirements.

Making the Machining Process Better

Often customers will go to order a basic shape and later machine down to a more shaped part, not realising what can be achieved from open die forging. By working with our technical sales team, we often achieve a shape closer to the finished product and optimise the production process enabling a faster lead time and more cost-effective solution.

To conclude, machining is an essential procedure in the manufacturing sector that makes it possible to create complex and accurate parts. Manufacturers can maximise their production workflows and produce high-quality goods by comprehending the various machining procedures and forging conditions that we offer here at Somers Forge.