What Is A Propeller Shaft?

Propeller shafts (tail shaft) are the main component of Marine shaftline. The pushing motion produced by a propeller results in the thrust action on the propulsion shaft. The forward end of the main shaft houses the main thrust block on the majority of ships.

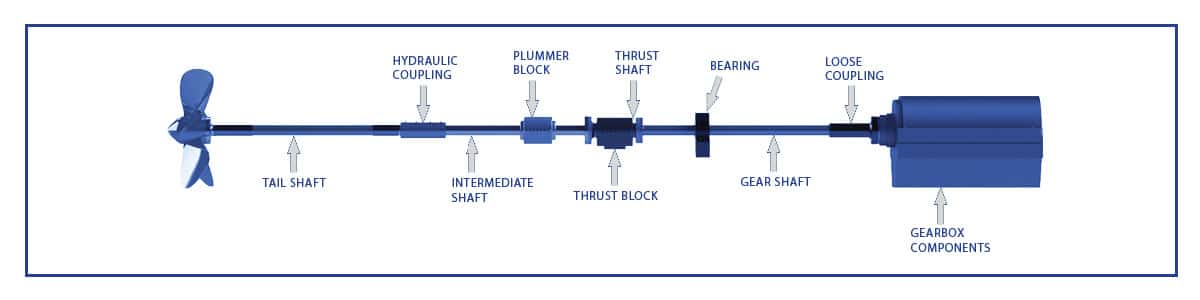

The propeller shaft line includes all of the parts, such as the flange coupling, engine components, thrust shaft, intermediate shaft, gearbox, and bearings that maintain the shaft in alignment, such as stern tube, strut, and spring bearings.

These components work together to form a robust shaft line, efficiently transmitting power from the engine to the propeller, ensuring the vessel’s propulsion system operates smoothly.

More emphasis is now being placed on more effective propulsion shafting design, due to the increased utilisation of propeller shaft power as well as the increased demand for noise reduction.

“Marine propulsion” refers to the system needed to provide thrust so that a boat or ship may navigate through water. The main engine, gearbox and propeller shaft comprise its essential components.

Here at Somers Forge, we supply all types of marine shaft forgings, specialising in tail shaft/propeller shafts. We have the expertise and capability.

Supplying Propeller Shafts

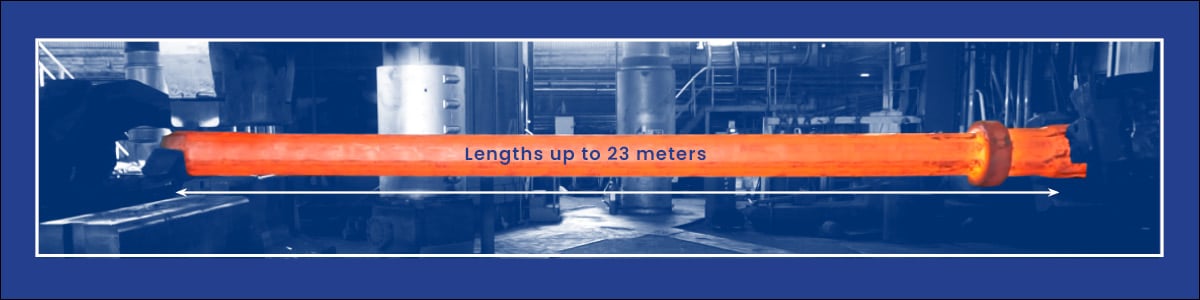

Depending on the use for which they are intended, we are able to produce propeller shafts in a variety of diameters and lengths up to 23 metres. For submarines, navy ships, patrol vessels, super yachts and cruise ships, we can provide a range of marine propulsion components, including the propeller shaft.

Inconel, C45, 34CrNiMo6, and stainless steel are the most popular materials we use to make shaft lines, but we can provide any material a customer requests. If needed, providing completed machining in addition to shaft forging.

Several loading types, such as torque moment, bending moment, axle thrust force, and transverse load, can be applied to the propeller shaft while it is in operation. Weather and sea conditions directly affect the life and wear of propeller shafts.

Propeller Shafts Refurbishment Services

Do you need a marine shaft to be renovated? At Somers Forge, we provide an in-house propeller shaft refurbishing service.

Restoring shafts to their original state; depending on the water environment, restored shafts may increase their lifespan up to further 12 years. Creating cost, time saving and lessening the impact on the lifecycle analysis. Get in touch with us today if your propeller shaft needs maintenance.

Our Marine Forgings

Somers Forge has been a leading provider of forged goods for the marine sector since our humble beginnings. We were awarded Admiralty Approval for the manufacture of propulsion shafting, propeller shafts and other related marine forgings back in 1912.

Useful Links

Marine Forgings | Forged Products | Marine Guide | Turbine Shaft | Propeller Shaft Forging Australia