What is forging?

Forging is the manufacturing process of hammering, pressing or rolling metal into shape. This is either delivered from a hammer, press or die. It is essentially the art of heating and working hot metal to design or shape that is fit for a specific purpose or use. By working the material, it increases many of its properties, including structure, conductivity and longevity. Forging offers a very useful and diverse medium for many industries with the process being economically sound and achieving specific mechanical properties. Forging is often categorised according to the temperature at which it is performed, cold, warm, or hot forging.

Materials which can be forged include carbon steel, alloy steel, tool steel, aluminium, stainless steel, duplex steel, copper, brass. The forging procedure will differ according to many factors, for instance, titanium forging will have different forging route compared to that of stainless steel forging. When the material is heated up to high temperatures in the region of 1200/1300 degrees centigrade, steel can be shaped into many different sizes of products. From your small 1kg items to 100-tonne size forgings. During the industrial forging process, the grains of the metal become elongated in the direction of flow. As a result, the toughness of the metal is substantially improved. A good forging design will ensure that the flow lines in the finished part lie where the component will come under maximum stress.

History of forging

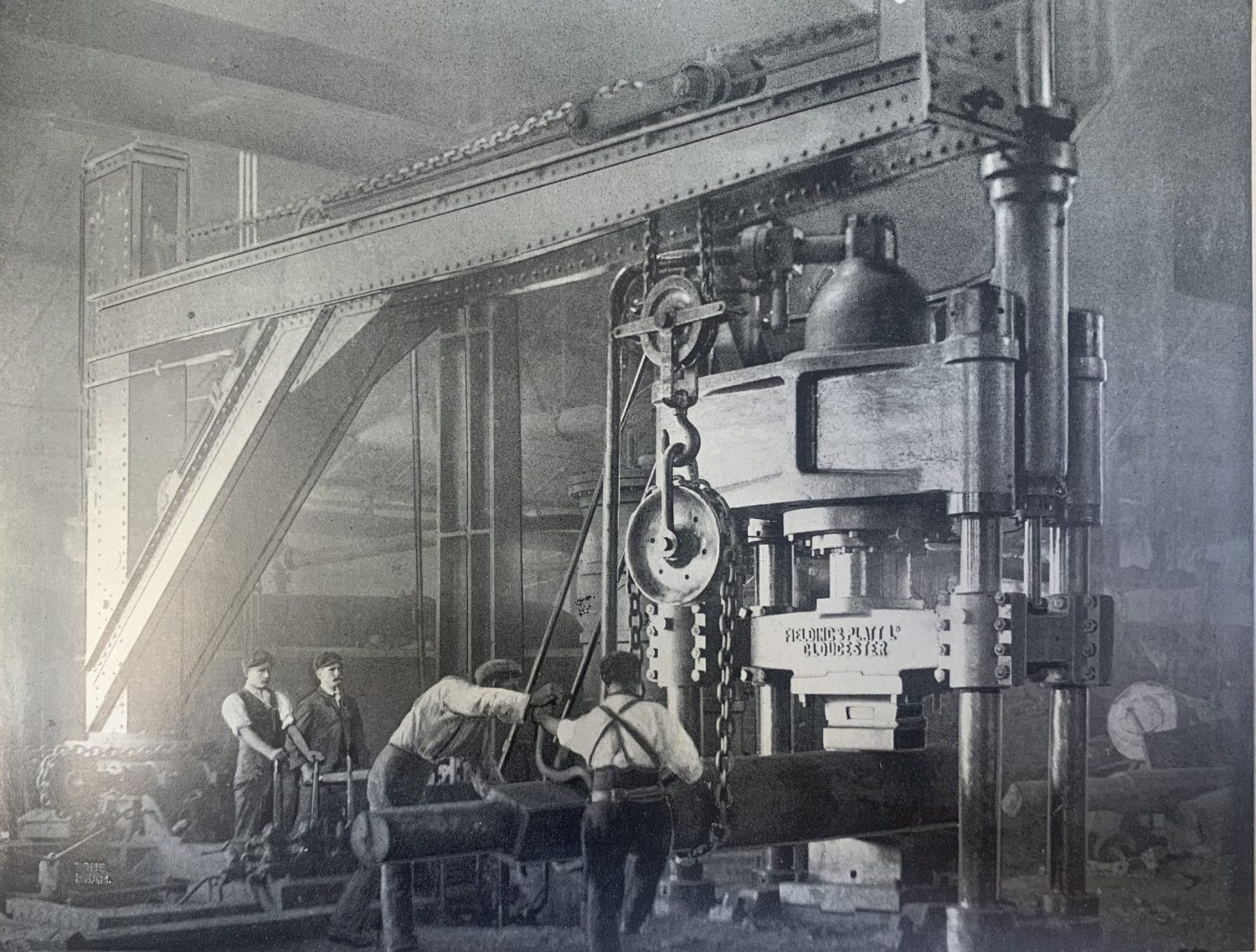

The forging of metals is one of the oldest working techniques of mankind. With pure metals such as gold and silver forged into jewellery and weapons around 4000 BC. The smelting and forging of iron with hammer and anvil have been directly linked to the 13th and 14th century. In the 15th century came the first big development in forging, with hammers mills built alongside rivers to harness the water flow. Somers Forge actually introduced the UK’s first stem hammer in 1850, when we were then known as Lye Forge. The 19th century saw the invention of the steam engine, which lead to modern forge engineering. This saw the development of powerful steam hammers and air hammers, eliminating the need for human power which had restricted the size of forged items before. Steel has been both a tool used by conquering empires right up to its use in modern engineering and construction.

Forging has evolved massively from the days of blacksmiths using a hammer and anvil to produce horseshoes. With advancements in equipment, from computers to robotics making the forging process now highly sophisticated resulting in more durable, efficient, faster engineering option. Nowadays industrial forging companies can produce forged parts in an array of material, shapes, sizes and finishes.

Here at Somers Forge, we are also part of this long line of history that makes up forging. With our founding in 1697, we are the tenth oldest family-run business in the United Kingdom. Our forge based in Halesowen located in the centre of the Black Country’s industrial region, has a timeline full of impactful events that have helped to make us a world-leading forge.

Different Types of Forging

The concept of forging is simply the manipulating of steel into a shape and this is the most sought-after metal component. There are many different industrial forging types each with different benefits.

Open Die Forging

Open die forging is when a die (hammer) strikes material on a stationary flat die, the metal is never completely restrained or confined by the die. The die is constantly hamming the metal with highly skilled forging operators responsible for achieving the desired final shape.

+ Greater microstructure & better fatigue resistance

– Machining is often required to achieve the desired finish

Closed Die Forging

Closed die forging also known as impression die, is the shaping of hot metal using two dies to achieve the desired shape in pre-cut dies. It is important to note that within closed die forging the heated material is approximately or close to the exact size and shape of the finished component.

+ Less machining is needed with tight tolerances achieved

– Setup cost is very high with cost dies to be produced

Roll Ring Forging

Roll forging in when flat bars are placed between two cylinder rolls which rotate and apply progressive pressure to shape the metal. This process reduces the thickness and enlarges the diameter.

Different conditions forgings are supplied in?

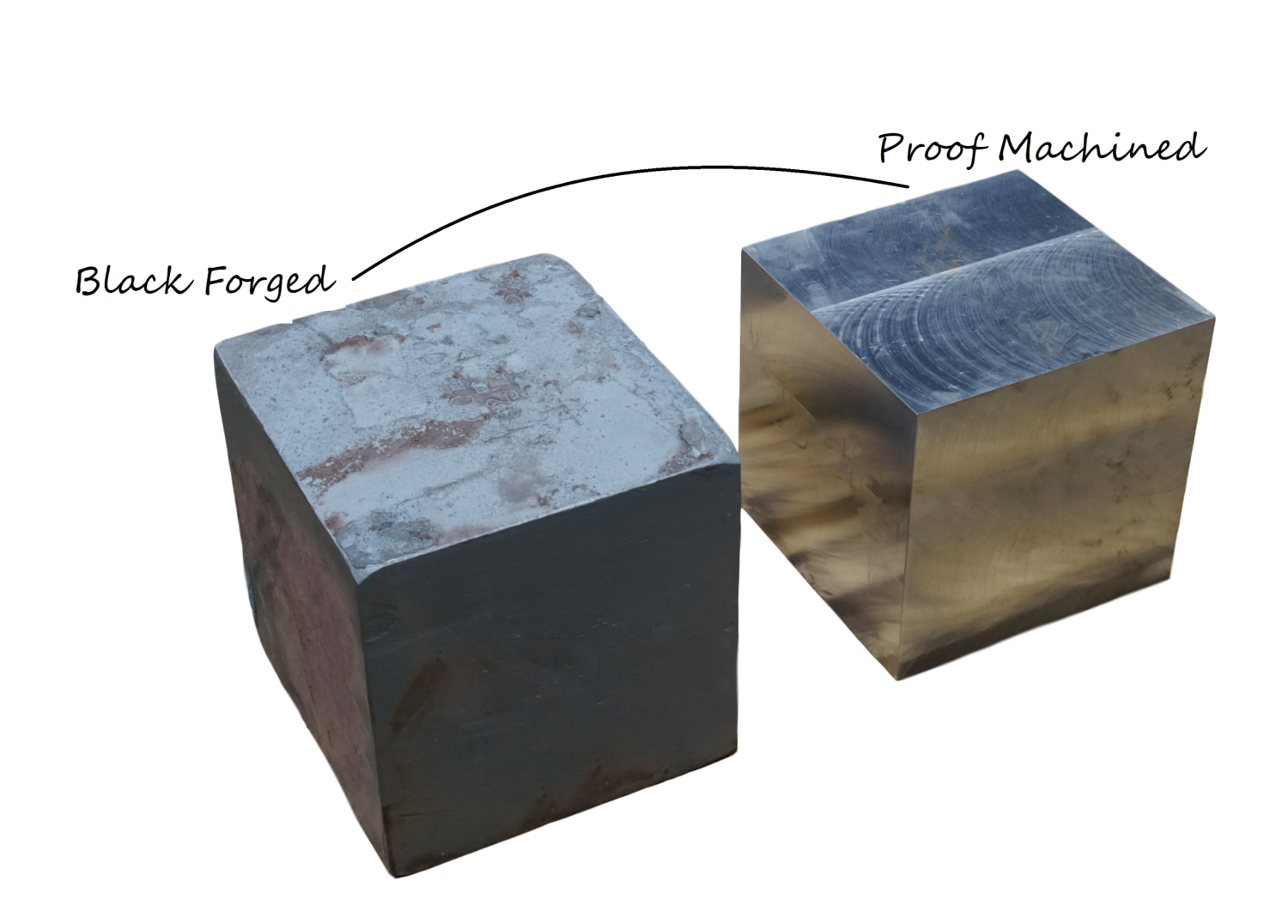

Forgings are supplied in many different conditions, from black forging (unmachined) to finished machine forging. The machining process is used to achieve specific measurements required for the products. There are many different machining methods used including, cutting, boring, turning, drilling, grinding, milling.

Black Unmachined Forging

A black unmachined forging is as the name suggests, not machined. The material will just be heat treated.

Rough Machined Forging

Rough machined is also known as proof machined. This is the process of knocking off the black scale on the forging in preparation for further machining processes.

Semi Machined Forging

This is where some shape is put into the piece but the final intricacies will be done later on. Operations such as threading, honing, polishing planning, milling, reaming are carried out to achieve semi-finished products. Having the item semi-finished saves time for the customer and frees their capacity.

Finished Machined Forging

Desired dimensions and surface finish are achieved. From here the finished machined forging would either go for testing if required or be installed.

Get Started With Us Today

Our goal here at Somers Forge is to build enduring relationships with clients by assisting them in overcoming their engineering challenges and helping them to increase their success within their industry.